SEE LARGE FOR OUR CUSTOMERS AND STAY CLOSE

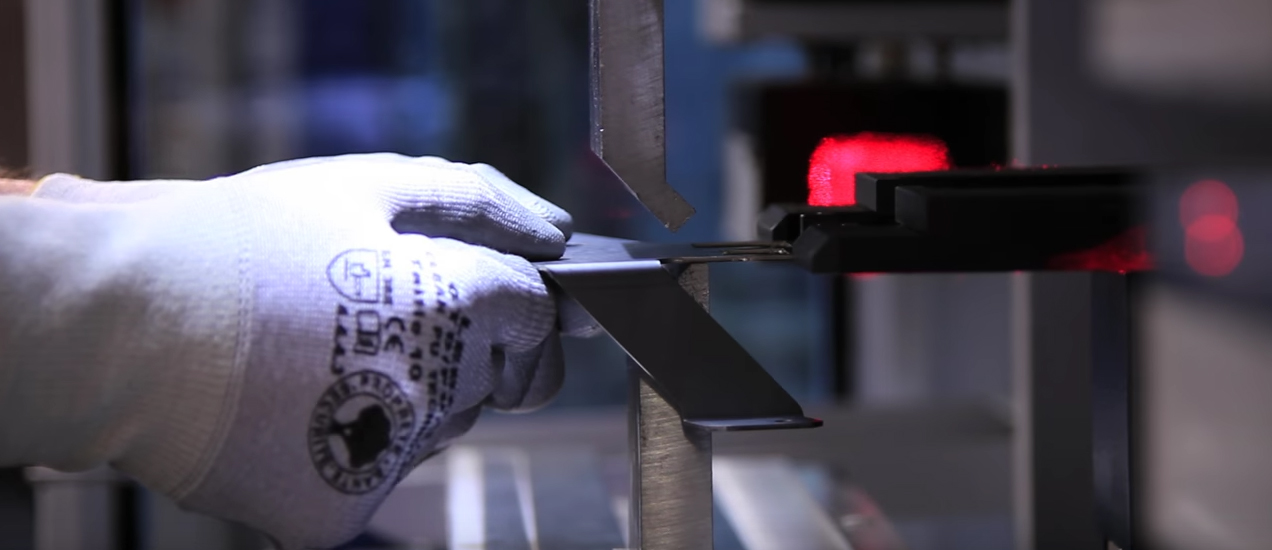

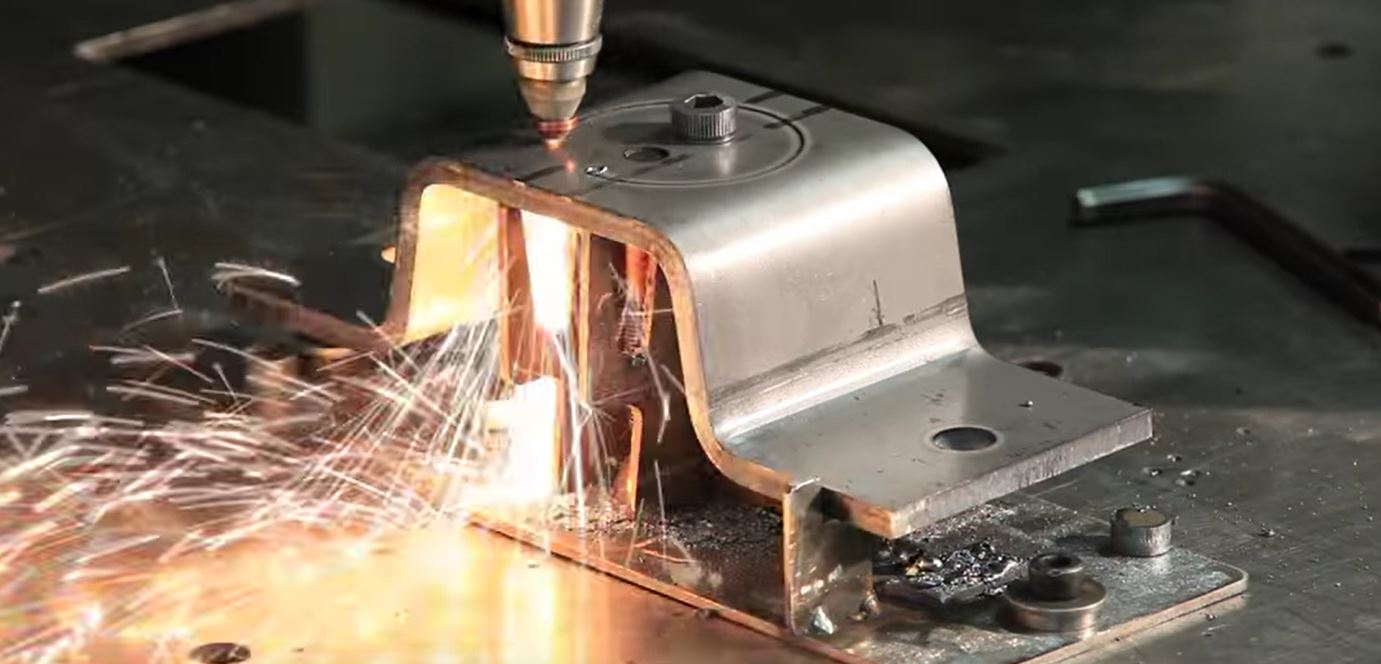

Specialists in thin metal parts from the prototype to the production line stage, Berard handles everything from the designer to the production of precision-made fine sheet metal, for all rolled and sheet metals, and across all industrial sectors. It is our aim to find the right technical solutions to meet our customers’ needs, and to run our production making full use of the entire value chain from the design phase to logistics

OUR REALIZATIONS

-

Frames and hoops

CHASSIS AND HOOPS

-

ADDE cinema cabins

ADDE cinema cabins

-

Part of series

Berard Fine Tolerie

-

DUPLICABLE

CHASSIS AND TOLERIE DUPLICABLE

OUR NEWS

-

BERARD : MOBILITY CHALLENGE

Mobility Challenge for Berard

-

Berard and subcontracting

Berard wants to protect himself from the vagaries of outsourcing

-

Berard and Navya board together

Berad and Navya

-

Berard is growing

berard extension

OUR VIDEOS

Berard is a member of UIMM LYON